We match our repair methods to the damage type, roofing material, and your long-term goals. There's no one-size-fits-all approach—proper repairs require selecting the right technique for each situation.

Patch Repairs for Localised Punctures and Small Damage Areas

When damage stays contained to a small area, patch repairs offer the quickest and most cost effective solution. We clean the damaged area thoroughly, removing any loose material and preparing the surface properly.

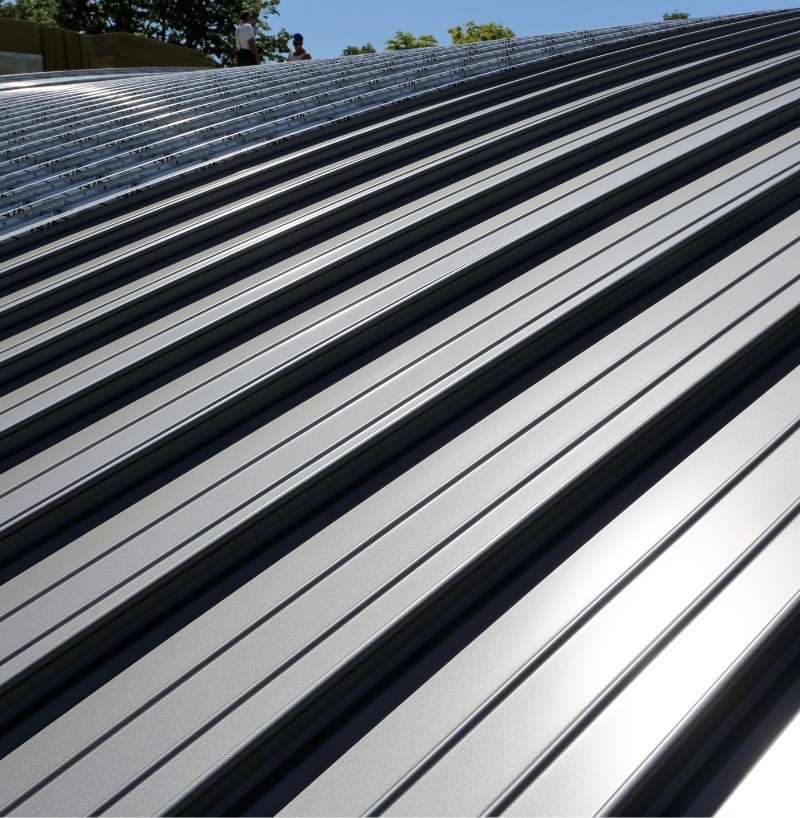

For membrane roofs, we apply a patch of compatible material using manufacturer-approved adhesives or heat welding. The patch extends well beyond the damage to create a reliable seal. Metal roofs get similar treatment, though we use appropriate sealants and may need to address any corrosion around the puncture first.

These repairs work brilliantly for isolated problems, getting you back to full waterproof protection without the expense of replacing entire sections.

Section Replacement When Damage Is Too Extensive for Patching

Sometimes damage spreads too far for patching to make sense. When we find extensive deterioration, multiple closely-spaced problems, or structural compromise, we remove the affected sections completely.

This involves carefully cutting out the damaged panels or membrane sections, checking the substrate and insulation underneath, and replacing anything that's been compromised by water damage. Then we install new materials that match your existing roof system, sealing everything thoroughly to integrate with the surrounding areas.

Section replacement costs more than patching but gives you essentially a new roof in the repaired areas. When damage is severe, it's the only sensible option.

Liquid-Applied Membranes and Seamless Coating Systems

For widespread surface wear, minor cracking, or ageing roofs that need refreshing across large areas, liquid-applied membranes provide a seamless waterproof barrier. We prep the surface by cleaning and repairing any major defects, then apply the liquid coating system in multiple layers.

These coatings flow into every detail, creating a continuous membrane with no seams to fail. They're particularly good for complex roof shapes with lots of penetrations, pipes, and equipment. The result is a fully renewed waterproof layer that can extend your roof's lifespan by 10 to 15 years depending on the material and condition.

Elastomeric coatings also reflect UV radiation and reduce heat absorption, which can cut your building's energy consumption by up to 25 percent in some cases.

Seam Repairs and Joint Sealing for Long-Term Waterproofing

Seams fail because thermal movement constantly works them loose. We remove the old sealant completely, clean the joint surfaces down to sound material, and apply new flexible sealants designed to accommodate expansion and contraction.

For membrane roofs with heat-welded seams, we may need to re-weld sections or apply seam tape and compatible adhesives depending on the membrane type. TPO and EPDM rubber roofing issues often involve seam failures requiring these manufacturer-approved repair methods.

Getting seams right takes patience and the right materials. Rushed repairs with incompatible sealants just fail again within months.